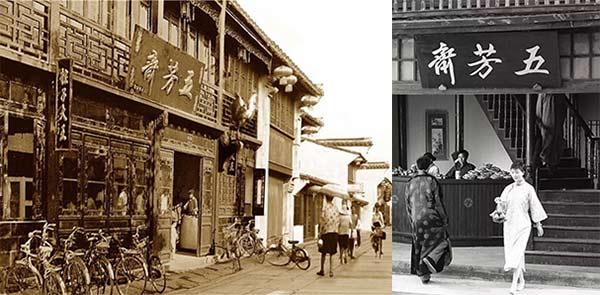

The former shop front of Wu Fang Zhai (Photo provided to chinadaily.com.cn)

Making?zongzi?requires 36 steps. Workers have specific instructions to produce each piece, from how to add?stuffing to the rice, weigh and shape each piece, to wrapping each pyramid-shaped dumpling by hand. There are also detailed standards as to where to put the stuffing, and the way to tie each piece with thread.

An electronic scale is in front of each worker, so each?zongzi?is made to a standard weight. For a 160-gram?zongzi, the error allowed is within 2 grams.?

While an automated assembly line has replaced much of the manual work, the part of wrappingzongzi?is still done by hand. Recently, the company announced that it is looking to spend 10 million yuan ($1.45 million) to develop robots that can replace humans to make?zongzi.

The materials for making?zongzi?are specially chosen from high-quality sources. The rice is from Northeast China's Heilongjiang province, the leaves wrapped around the?zongzi?are from?high mountains in Jiangxi province, and the meat filling is made of fine-selected pork hindquarters from exclusive pig farms in Henan and Zhejiang provinces.

Hu Jianmin is the fourth generation inheritor of this intangible cultural heritage. He said that azongzi?wrapping technician needs to train for five months. Many technicians have worked at Wu Fang Zhai for more than 20 years, and the fastest record is wrapping seven?zongzi?in one minute.