People pass the gate of Panasonic's battery plant in Beijing Thursday. (Photo: Chen Qingqing/GT)

Move reflects sluggish demand, not strategic change in market

Japanese electronics giant Panasonic Corp plans to close a battery factory in Beijing, but the move will not affect the company's overall strategy in the Chinese mainland, Panasonic's PR representative in China told the Global Times Thursday.

About 1,300 employees will be laid off as a result, the person said on condition of anonymity. Of those, 750 are regular workers and 550 are from outsourcing companies, she noted.

Located in the Beijing Economic and Technological Development Area, the factory, also known as SANYO Energy (Beijing) Co, has specialized in producing small lithium ion batteries for consumer electronics devices such as tablets and laptop PCs, according to a document by the company sent to the Global Times Thursday.

The factory was still operating normally as of Thursday.

Panasonic is holding discussions with the staff about severance pay, with layoffs scheduled for the end of August, the PR representative said.

"Declining demand for the factory's products in recent years is the main reason for the shutdown," she said, noting that closing one factory does not reflect any change in Panasonic's strategy in China.

In July 2010, Panasonic announced it would offer about 818.4 billion yen ($9.4 billion) to buy SANYO Electric Co, according to the company's website.

The purchase made SANYO a wholly owned subsidiary of Panasonic.

The deal was completed in December 2010 with the acquisition of about 3.1 billion shares of SANYO for approximately $4.6 billion, according to media reports.

By taking over SANYO, Panasonic aimed to double the production capacity of lithium ion batteries to about 1 million units a year, Chicago-based market consultancy Zacks Investment Research said in a research note shortly after Panasonic announced the deal.

The acquisition would also help Panasonic compete with rivals such as Sony Corp and Hitachi in rechargeable power devices used in mobile phones, laptop PCs and digital cameras, according to the note.

There is now a pricing battle in China for these products, and foreign lithium ion battery manufacturers are facing more severe competition, Wang Jiahong, analyst from Beijing-based CCID Consulting, told the Global Times Thursday.

"For example, a small-scale domestic manufacturer will sell at a price about 50 percent lower than that sought by foreign companies," Wang said.

He noted that an increased number of Chinese companies are now making lithium ion batteries for consumer electronics.

Panasonic emerged as the leading lithium ion battery cell supplier to the global market for the first half of 2015, German photovoltaic industry publication pv magazine reported earlier in August, citing data compiled by South Korean research organization SNE Research.

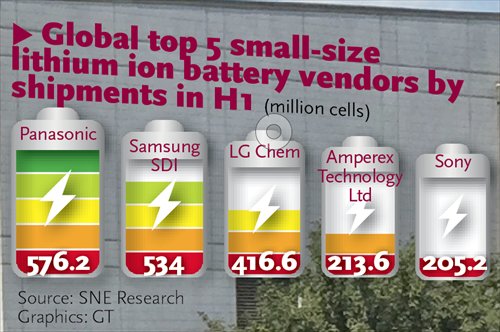

Panasonic held 20.5 percent of the global market in the first half of 2015, having shipped about 576.2 million cells. Samsung SDI Co was next with 19 percent (534 million cells), according to pv magazine.

Leading South Korean chemical company LG Chem was in third position with 14.8 percent followed by Chinese company Amperex Technology and Sony.

However, analysts attributed Panasonic's strong showing as being largely due to its supply of cylindrical batteries to Tesla Motors Inc, according to pv magazine.

Panasonic shipped 285 million cells to Tesla in the first half of 2015, Byeongju Kim, director of SNE Research, was quoted as saying in the media report. Although South Korean manufacturers have begun supplying Tesla, no high-volume deals have been signed, Kim noted.

It is unclear if Panasonic will transform its factory in Beijing to a new plant producing cylindrical batteries for electric cars, said Wang from CCID Consulting.

"Reconfiguring the factory requires introducing new technologies as well as building new production lines, which will take a long time," he noted.